4 Projects Prepping Seniors for Careers in Mechanical and Civil Engineering

The university’s flagship project and a Panther rite of passage, the engineering and science student design and research program has existed in some form or another almost since the university’s inception in 1958.

A multidisciplinary capstone project for all science and engineering seniors, senior design is a yearlong course in which students bring a project from concept to completion, simulating a real-world work environment and culminating in the Northrop Grumman Engineering and Science Student Design Showcase, where teams present their work and field questions from peers, faculty, industry professionals and local leaders.

Due to the COVID-19 pandemic, this year’s seniors, like the rest of the world, had to adapt to unforeseen challenges, like in-person class cancellations and short-notice closure of the L3Harris Student Design Center. While most students’ projects look a little different from how they had envisioned them at the beginning of the year, we are proud to continue the tradition of showcasing them to their peers, community and, most important, prospective employers through the Northrop Grumman Virtual Student Design Showroom.

Prepare to be impressed—the showroom hosts descriptions, photos, video presentations, display boards and more for the more than 100 projects completed this year.

Here, we’ve compiled a list of…

4 Projects Prepping Seniors for Careers in Mechanical and Civil Engineering

1. Autonomous Farming in Space

To expand and accommodate human life beyond Earth, we’ll need to figure out how to effectively grow food in space. This student design team’s mission was to do just that. In the project, “Autonomous Multiple Cycle Farming in Space,” students came together to build an autonomous farming system that “grows plants autonomously through robotic functions with limited human interaction for multiple cycles.” See how it works in the video above!

The team has also submitted the project to two NASA programs: Technology Advancement Utilizing Suborbital Flight Opportunities “Tech Flights” and Student Payload Opportunity with Citizen Science (SPOCS) at Johnson Space Center.

Team Lead

Courtney Cline

Team Members

Dominic Allard, Philip Bernhard, Joshua Calhoun, Courtney Cline, Giampiero Corsbie, Timothy Frazier, Kali Jenson, Bryce Johnson, Christopher Millsap

Faculty Advisors

Philip Chan, associate professor, computer engineering and sciences

Elisabeth Kames, visiting instructor, mechanical and civil engineering

2. Lockheed Martin Mechanical Design Project

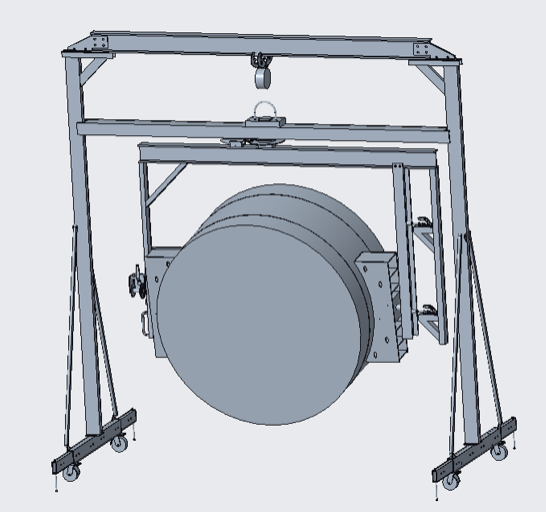

For this student design project, students had the unique opportunity to work directly with Lockheed Martin, an American aerospace, defense, arms, security and advanced technologies company located here, in Melbourne, Florida. Lockheed Martin asked the students to design a lab fixture that can lift and rotate a 2,000-pound cylinder and set it down in both its horizontal and vertical positions.

“The final design consists of three sub-assemblies, including lifting, rotation, and gripping. A large frame with a pulley lifting system, a rotating structure that can rotate the cylinder about the Y and Z axes, and a gripping mechanism with which to secure the cylinder.”

Team Lead

Madison Moyer

Team Members

Alexander Alamed, Adam Bettencourt, Ivan Chernokolpakov, Sarah Hopkins, Jacqueline Isom, Daniel Liyunam, James O’Connell

Faculty Advisors

Elizabeth Kames, visiting instructor, mechanical and civil engineering

Chiradeep Sen, assistant professor, mechanical and civil engineering

3. Leonardo DRS: Optimization Using Additive Manufacturing

Working with Leonardo DRS, a defense contractor company in Melbourne, Florida, students were asked to optimize existing company parts, currently manufactured traditionally, for additive manufacturing. The team explored how to use the latest technology in manufacturing to make the system more efficient—reducing weight and temperatures.

“In conclusion, this project not only demonstrates what the future holds given the capabilities of additive manufacturing, emphasized with the results of this new system, but it also ensures that this nation’s Soldiers in the field can perform as efficiently and effortlessly as possible. Reducing the weight and temperatures of a system that is operated by these individuals will ensure efforts to produce less fatigue and wear on the Soldiers, maximizing mission effectiveness and safety for our troops.”

Team Lead

Reid Chaconas

Team Members

Raymond Francois, Michael Young, Diego González

Faculty Advisor

Elisabeth Kames, visiting instructor, mechanical and civil engineering

4. Florida Tech Motorsports: Formula SAE

In a project that goes to an annual FSAE competition each May, this team’s objective was to reduce the overall weight of a Formula-style vehicle by 80 pounds. To achieve this goal, the team redesigned crucial components of the vehicle using carbon fiber. Members were able to create an aerobody that weighed just 20 pounds, a third of the 2019 team’s vehicle weight.

Team Lead

Christopher Rider

Team Members

Patrick Angelo, Navid Babwah, Ayze Feyza Boyun, Julio Burbano, Raymond Cromin, Marianne Fortin, Matt Gallene, Hussam Jambi, Wenxin Li, Collin Redden, Alec Spooner, Hailiang Wang, Zilin Xu

Faculty Advisors

Elisabeth Kames, visiting instructor, mechanical and civil engineering

Ronnal P. Reichard, professor, ocean engineering and marine sciences

Impressed and ready for more? Check out:

- 5 Projects Prepping Seniors for Careers in Computer Engineering and Sciences

- 2 Projects Prepping Seniors for Careers in Mathematical Sciences

- 4 Projects Prepping Seniors for Careers in Biomedical and Chemical Engineering/Sciences

- 5 Projects Prepping Seniors for Careers in Ocean Engineering and Marine Sciences

- 4 Projects Prepping Seniors for Careers in Aerospace, Physics and Space Sciences.