Alumni at Rocket Crafters Using 3D Additive Manufacturing for Hybrid Rocket Engines

3D Additive Manufacturing & Hybrid Rocket Engines

Based in Titusville, just a short hop away from the Kennedy Space Center, Rocket Crafters, Inc. is developing breakthrough hybrid rocket engine technology with their patented 3D additive manufacturing process.

As the demand for small satellites continues to accelerate, Rocket Crafters’ proprietary D-DART ™ technology will provide a safe, affordable and customer-responsive means for launching SmallSats.

Two Florida Tech alumni are currently part of this new evolution in rocket technology at Rocket Crafters Inc. (RCI).

Florida Tech Alumni on the Forefront of Hybrid Rocket Technology

Michael Robison, aerospace engineering ’15, is a propulsion engineer and the lab scale test director for RCI. He is responsible for signing off on all the procedures and events as well as initiating the auto-ignition sequence.

“I believe my education from Florida Tech prepared me for my current position with RCI. I not only had some amazing professors, but also having the hands-on perspective was awesome. Being in clubs such as the Student Rocket Society and American Institute of Aeronautics and Astronautics helped me gain experience in the rocketry and space field.”

Picking his favorite thing about his job is a bit of a challenge for Robison. Above all else, he says he loves working with “the brightest people I’ve ever met.”

Kineo Wallace, aerospace engineering ’17, works closely with Robison as a propulsion engineer.

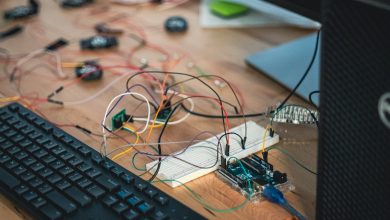

Wallace’s primary role is R&D as well as testing the D-DART™ technology with hybrid rocket engines. The technology essentially allows RCI to 3D print fuel grain out of ABS plastic.

One of the benefits of working with a small and nimble start-up is that is allows Wallace and Robison to work on a wide range of projects. In addition to R&D, Wallace is the primary concept designer for RCI’s mobile launch platform for the Intrepid-1 rocket expected to be in service next year.

Like Robison, Wallace was also actively involved with Florida Tech’s Student Rocketry Society.

“My freshman year I was a team lead for the Maximum Altitude Hybrid Rocket Competition for Student Rocketry Society; little did I know that the propulsion technology we were using was the exact same technology that I’m working with now. It turns out that Florida Tech was and still is licensing the fuel grain tech from Rocket Crafters. Which is why we always win the competition!”

Being on the cutting-edge of rocket technology means Wallace and Robinson never quite know what adventure lies before them each day.

“This is truly a job that lives up to the saying that if you “Choose a job you love, and you will never have to work a day in your life!” says Wallace.

The future not only looks bright for Wallace and Robison, but for RCI as well. RCI’s co-founder and chief technologist, Ronald Jones, was recently awarded a U.S. Patent for their additive manufacturing technology, aka 3D printing.

What is a Hybrid Rocket Engine

Rocket Crafters’ CEO and former astronaut Sidney Gutierrez explains:

https://youtu.be/CmBw4H-il8o

https://www.youtube.com/watch?v=BVPxbdkC1y8