Follow the Bouncing Pile

The bridges and overpasses of Florida’s highways and roads are supported by massive, post-like pieces called piles. You may have seen and heard piles being driven deep into the ground. Installing these supports is expensive and complicated plus Florida’s mixed geologic deposits with very fine sand, silt and clay cause the piles bounce back up when they are hit with the pile driving hammer.

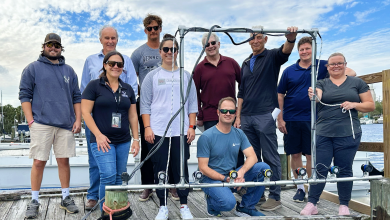

Yes, these 80,000-pound concrete behemoths bounce up to 3 inches as they are being pounded into the ground. “The sand just tosses it back up,” said Florida Tech civil engineering professor Paul Cosentino, who has been researching this phenomenon for more than a decade, with a research team that has included Drs. Edward Kalajian, Albert Bleakley, Yahya Sharif Sharaf-Eldeen, Matthew Jensen and Charles Bostater. They have studied large construction sites throughout Florida, including currently the $2 billion Wekiva Parkway improvement project.

Though a few inches don’t seem like much, that bounce requires the construction team to check the pile load bearing capacity, stopping their work for up to 24 hours. During this time engineers are counting on the soil to properly remold itself around the pile to produce it required capacity. And the pile itself, as well as the driving hammer, can be badly damaged, Cosentino said.

“When concrete piles are hit with the hammer the combinations of stresses can either crush the concrete in compression or cause it break right off the bottom of the pile when the concrete is in tension– and we don’t break a little bit off. We’ll break 12-15 feet of concrete off the pile.” A simple toy like a slinky is often used to demonstrate these effects.

All of this costs the project two of the biggest factors in construction: time and money.

Cosentino is currently teaming with another Florida Tech faculty member, Physical Oceanography and Environmental Sciences associate professor Charles Bostater, to develop a potential solution that introduces new technology into this complex process.

They are using Bostater’s high-speed video camera to produce very accurate readings on how much the pile has moved when hammered. The research team marks the piles with markers specifically for Bostater’s camera. The camera records the driving and software is used to check the light intensity changes. Accuracy of movements down to a single pixel, have the research team excited as to its potential final use.

They are using Bostater’s high-speed video camera to produce very accurate readings on how much the pile has moved when hammered. The research team marks the piles with markers specifically for Bostater’s camera. The camera records the driving and software is used to check the light intensity changes. Accuracy of movements down to a single pixel, have the research team excited as to its potential final use.

The identification of movement is key. Current standards require less than a quarter of an inch bounce as acceptable for installation. The camera can closely monitor the piles in a way the pile driving inspector cannot and provide data to within a 10th of a millimeter. The camera can also produce visual displacement of a pile for the first time ever.

“The camera allows for visual confirmation of these movements,” Cosentino said. “We’re visual type engineers, so the more we can see, the more we can step back and make a decision on what the to do to change things.”

The ultimate research and development goal would be for our research team to provide the pile driving contractors with a simple to use system that warns them of problems from pile rebound.

Cosentino and Bostater are gathering data on the high-speed cameras and will report to the Florida Department of Transportation in November.

###