Chemical Engineering Students Design Power Plant to Reduce Carbon Emission

As the world’s carbon dioxide levels continue to climb, chemical engineering students are collectively rising to the challenge of reducing the amount of CO2 produced by power plants.

The team’s senior design project focused on creating a power plant design prototype that produced power through biomass and geothermal sources that had the potential to produce zero carbon dioxide emissions.

Biomass power production uses waste wood as an energy source and geothermal power production relies on the Earth’s internal heart energy to produce power. Chemical engineering students built a prototype that relies on these two sources of energy and a novel conversion design that helps capture CO2.

The Challenge of Carbon Emission

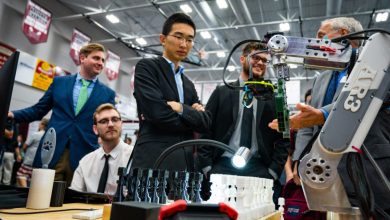

The three-person team included; Andrea Brooks, Ryan Tu and Stephen Jamunar.

“The members of our team all have an environmental focus within our chemical engineering program,” Jamunar said. “We were inspired to do something that would benefit the environment.”

Stephen admits that the group faced a great deal of challenges in the initial stages of their design because unlike some other senior design presenters, they were starting something from scratch rather than improving on a previously completed process.

“It goes without saying that this was very difficult, as there was no literature that we could compare to,” Jamunar said. “We also had the issue of simulating our results in the software we were provided, ASPEN.”

ASPEN is an intuitive program that the team, as well as other chemical engineering students in their class, were taught to use in designing and simulating power plants.

With the complex resource materials that they were using however, there was no actual database that they could use in their biomass plant. This is why they had to implement what is known as the “Black Box” method, which involved literature values and extensive handwritten calculations.

It was then that they discovered something that amazed them.

Carbon Emission Eureka

“In the beginning, we were simply trying to design a plant prototype that would not emit any carbon dioxide through the sequestration of CO2,” Jamunar said. “Then we realized that the waste repurposing process we designed to take our carbon dioxide from the ground to the surface, could be used to modify any plant.”

The team realized that this concept could be added on easily to all power plants in the world that have the space for a secondary plant, such that if every plant were to adopt it has the potential to drastically reduce carbon emissions and help address climate change.

Qualms

“The only issue that some people indicated about our green process was the fact that we used some coal in the biomass plant,” Jamunar said. “The reason we added coal to the wood chips resource was to improve the efficiency of the combustion and generate more heat.”

The team did this to maximize their plant’s profitability, as they had always been taught that economics is the bottom line in efficient engineering.

“I guess that to make it a completely green process, we would eliminate the coal and only use wood chips as our main resource,” Jamunar said. “That would be our only change.”

Going forward

“This has definitely been the best learning experience while pursing my degree degree that we will all use the experience gained in our careers,” Jamunar said. “We would like to enter the power industry but even if we don’t, just going through the entire process design and costing gave us a real-life taste of what we will be doing in the industry as engineers.”

Stephen’s best advice for future senior design presenters is to start working on their projects early. “You usually have an entire year to work on it and this time is valuable,” Jamunar said. “There is a lot of work that needs to be covered and you will always find yourselves running into problems so start early and try to get rid of all the little bugs.”

The team unanimously agrees that the importance of teamwork is definitely the main takeaway from the entire experience. There were times that they disagreed but they always worked out solutions, and they are confident that knowing how to do so will definitely help them all in the industry.