A Mechanical Engineering major’s Paradise—The Machine Shop

Good day Panthers! I hope everything is going just as wonderful as it is for me here in my natural habitat, Florida Tech. As I move further into the school year, I have progressively become busier and busier with extracurricular activities, school work, and having fun. This hectic and fast paced lifestyle does not apply only to me, but pretty much to every panther that wants to take full advantage of their experience here on campus.

Academically speaking, my experiences have taken a very intriguing turn for me. Being a mechanical engineer major, I have always loved building things. I was the little girl that knew how to use a power drill before learning how to do my hair. That being said, you can probably imagine my excitement when I found out that there would be an introductory course to the machine shop for my Intro to Mechanical Engineering class!

For the lab, half of the class would be split up to go to the machine shop for the first three weeks and the other half would stay behind in the computer lab to learn how to use Pro-E (an engineering software used for designs) and then the two groups would switch places. I wanted to dive right into the hands on projects and get my hands dirty with machine grease, so I was even more excited when I found out I was in the group that would start with machine shop!

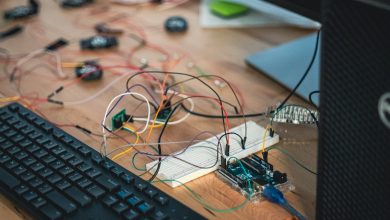

The first few days of machine shop were spent going over safety precautions, where everything is stored and what the basic tools and machines were used for. After all that housekeeping it was time to get to the fun stuff: playing with power tools and making little projects. Our first project was very basic and simple. We had to cut a 2” by 2” square of aluminum, file down the edges to smooth it out, put layout fluid on it, measure five centering points with micrometers where the holes would be drilled, mark out the holes with a tap then drill the holes and thread the center one. To simplify all that engineering jargon, basically we created a block with five holes in it that had to fit onto another block with five sticks

The first few days of machine shop were spent going over safety precautions, where everything is stored and what the basic tools and machines were used for. After all that housekeeping it was time to get to the fun stuff: playing with power tools and making little projects. Our first project was very basic and simple. We had to cut a 2” by 2” square of aluminum, file down the edges to smooth it out, put layout fluid on it, measure five centering points with micrometers where the holes would be drilled, mark out the holes with a tap then drill the holes and thread the center one. To simplify all that engineering jargon, basically we created a block with five holes in it that had to fit onto another block with five sticks  on it.

on it.

The whole process was extremely fun for me. I was the first one in my class to finish my block, and it fit perfectly on the rig. That being said, my machine shop teacher was a bit impressed at the fact that I am the only female mechanical engineering major in that class and I was able to do the job the fastest and most precise. It was really great being able to teach the guys how to thread a hole too (yes, I am bragging). This week, we’re going to learn how to weld metals together. I’m so excited since I have never used a welding machine before!

This is what Florida Tech is all about. Getting the formal education with the hands on experiences that keeps you intrigued and excited to learn. It really is the ‘high tech with a human touch’ that is promised to you from day one.

Here are a few pictures on the creating process of my cute block of aluminum. Leave a comment and let me know what you think of my craftsmanship! Until next time panthers!